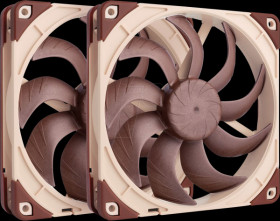

NF-A14-X25 G2 PWM SX2-PP NOCTUA NF-A14-x25 G2 PWM Sx2-PP

reichelt elektronik

RSS

80.51 EUR343.46 PLN

RSS

80.51 EUR343.46 PLN

- Sklep zagraniczny

- MPN:

- NF-A14-X25 G2 PWM SX2-PP

- Kod:

- 410177

- Producent:

- Noctua

- GTIN-13:

- 9010018100655

- Waluta:

- euro

- Dodany do bazy:

- Ostatnio widziany:

The NF-A14x25 G2 PWM Sx2-PP is a set of two NF-A14x25 G2 PWM 140mm square frame fans that are slightly offset in speed, which can be advantageous in push-pull operation as well as in situations where two fans are operated side by side, e.g. in case cooling applications or on 280mm water cooling radiators.

When two fans run at nearly the same, constant speed in a push-pull configuration or side-by-side, their acoustic interaction can lead to unwanted harmonic phenomena such as intermittent vibrations or periodic humming due to interference, which can be heard as beat frequencies. Therefore, the two NF-A14x25 G2 PWM fans included in the Sx2-PP set are slightly offset in speed (+/- ~25rpm) to avoid such phenomena. This fine-tuning is made possible by the fans' novel etaPERF™ motor and its NE-FD6 driver IC, which achieves extremely precise speed control and, thanks to its SupraTorque™ function, can utilize additional torque margin to maintain the desired speed even when working against significant flow resistance, such as on water cooling radiators and heat sinks.

Since one fan runs slower at ~25 rpm (PPA) and one runs faster at ~25 rpm (PPB), intermittent vibrations or periodic humming can be effectively prevented while maintaining the same overall cooling capacity. Especially since the perception of beat frequencies can vary depending on psychoacoustic preferences, users can easily further optimize the acoustics by running the PPA fan slightly slower via the PWM control or the included low-noise adapter, resulting in an even more pleasant noise signature due to the increased offset.

Double fan set for push-pull and side-by-side operation

The Sx2-PP set consists of two NF-A14x25 G2 PWM fans whose speed is offset by +/- ~25rpm to avoid unwanted acoustic interaction phenomena. It is the ideal choice for push-pull configurations as well as for situations where two fans are operated side by side, e.g. on 280mm radiators or in typical case cooling applications.

Next generation performance level

Noctua's renowned NF-A14 has received over 100 awards and recommendations from international trade publications and is considered one of the best 140mm fans on the market. With its even higher efficiency and new state-of-the-art design, the NF-A14x25 G2 represents a further innovation boost in terms of performance level and manufacturing technology.

Highly optimized P/Q characteristic curve for all applications

The advanced aerodynamic design of the NF-A14x25 G2 enables an extremely strong pressure/flow performance curve (P/Q), particularly in the critical mid-range. This makes the NF-A14x25 G2 a real all-rounder that works excellently in both pressure-sensitive and flow rate-sensitive applications.

Excellent application acoustics

While many fans produce unpleasant, high-pitched running noises as soon as they are mounted in typical applications such as on coolers or radiators, the NF-A14x25 G2 has been carefully optimized for optimum application acoustics: Even at high dynamic pressure, the fan impresses with an even, pleasant frequency profile and surprisingly low sound pressure levels.

Progressive bend impeller

The NF-A14x25 G2 uses an innovative progressive bend impeller with flow acceleration channels and winglets. Its nine fan blades are angled backwards close to the stroke and increasingly bent forwards towards the outside. Together with the centrifugal turbulator hub, this design not only helps to push more air into the outer, more efficient zones of the fan blades, but also ensures maximum lift and an almost uniform load on the blades over the entire length.

Centrifugal turbulator hub

The new centrifugal turbulator design acts on the one hand as a turbulence generator, which enables improved adhesion of the air flow in the hub area. At the same time, the rotational movement pushes air centrifugally from the hub area (where aerodynamic efficiency is low due to the low rotational speeds) to the outer, more efficient zones of the fan blades, resulting in higher overall efficiency.

Flow Acceleration Channels

The impeller of the NF-A14x25 G2 is equipped with so-called flow acceleration channels on the intake side. By accelerating the airflow in the critical outer regions of the fan blades, suction-side vortex shedding is reduced, resulting in higher efficiency and lower turbulence-related noise emissions.

Winglets

Winglets can help to avoid wake vortices at the blade tips caused by the pressure difference between the suction and pressure sides of the fan blade. On the other hand, winglets carry the risk of reducing overall efficiency due to additional fluid displacement in areas with high speeds. The small winglets of the NF-A14x25 G2 have been carefully optimized to achieve consistent efficiency increases in combination with the progressive bend blade geometry, the flow acceleration channels and the AAO frame.

Minimal wheel gap

The NF-A14x25 G2 has an unprecedentedly narrow impeller gap (distance between blade tips and inside of frame) of just 0.7 mm. This extremely ambitious design sets a new record for 140mm fans and contributes to superior performance at higher dynamic pressure, such as on radiators and coolers, because there is less leakage through the gap between the rotor and frame.

Sterrox® liquid crystal polymer

The rotor of the NF-A14x25 G2 is made of Noctua's novel Sterrox® Liquid Crystal Polymer (LCP), which is characterized by extreme tensile strength, an exceptionally low coefficient of thermal expansion and excellent damping characteristics that are ideal for reducing resonance and vibration phenomena in modern fan blade designs.

AAO frame system

Noctua's AAO (Advanced Acoustic Optimization) frames feature integrated vibration buffers as well as a stepped inlet design and inner surface microstructures for even better performance/noise efficiency.

Stepped Inlet Design

The stepped inlet area of the stepped inlet design creates more turbulence in the inlet. This facilitates the transition from laminar to turbulent flow, which adheres better to the frame (flow attachment) and thus increases the suction capacity of the fan, especially when the intake area is limited.

Inner Surface Microstructures

The microstructure in the inner area of the frame (Inner Surface Microstructures) creates a boundary layer through which the tips of the fan blades move. This reduces the flow separation from the suction side of the blade tips, which results in a significant reduction in rotational noise and an increase in pressure and airflow efficiency.

Anti-vibration sealing lip and pads with load reduction

The NF-A14x25 G2 is a high-precision device with very tight tolerances. It is therefore important to avoid excessive forces acting on the frame, especially when installing the fan on water cooling radiators. To avoid problematic loads, the NF-A14x25 G2 is supplied with a customized anti-vibration gasket (pre-installed) and anti-vibration pads on the output side, which have integrated relief structures to reduce possible deformations to a minimum.

Integrated anti-vibration pads

Made of extra-soft silicone, the anti-vibration pads reduce the transmission of minimal vibrations and are compatible with all standard mounting systems and fan brackets used with CPU coolers.

Anti-vibration sealing lip for water cooling radiators

The NF-A14x25 G2 comes with a pre-installed NA-AVG2-LR silicone seal on the outlet side of the fan. The sealing lip helps to dampen minute vibrations and reduce air loss between the fan and the application, ensuring optimal cooling performance for water cooling radiators or other situations where a tighter seal is beneficial.

Spacer for suction applications (sold separately)

If sufficient space is available, the NF-A14x25 G2 can be combined with the optional NA-IS1-14 spacer to reduce turbulence in applications where the fan draws air through grilles, mesh panels, filters or perforated plates. In many configurations, this reduction of air turbulence can improve both the airflow performance and the intake acoustics of the fan.

SSO2 bearing system

The NF-A14x25 G2 is equipped with the further optimized second generation of Noctua's proven SSO2 bearing system. With SSO2, the rear magnet is positioned closer to the fan axis, resulting in even better stabilization, which leads to further improved precision and durability.

Metal bearing shell

The NF-A14x25 G2 uses a CNC-milled brass bearing shell to guarantee the highest possible level of manufacturing precision, minimal tolerances and outstanding long-term stability.

etaPERF™ motor with NE-FD6 PWM IC

Noctua's new etaPERF™ motor sets new standards in terms of energy efficiency thanks to its groundbreaking low electrical impedance. At the same time, the NE-FD6 driver chip with its integrated, ultra-sensitive Hall effect sensor ensures extremely precise commutation. In combination with Noctua's proven Smooth Commutation Drive 2 technology, this makes the etaPERF™ motor virtually inaudible on the one hand and enables it to convert a minimum of electrical energy into a maximum of fan performance with virtually no loss on the other.

SupraTorque™

Most fans lose speed slightly when they have to work against high flow resistance on heat sinks or radiators, which results in lower cooling performance. The SupraTorque™ technology of the NE-FD6 driver chip, on the other hand, allows the fan to call up additional torque reserves when required in order to keep its speed at the desired level even at maximum dynamic pressure and thus guarantee constant performance even under the most difficult conditions.

PWM control with a wide speed range

The NF-A14x25 G2 PWM can be throttled from its maximum speed (1500rpm) down to 300rpm using pulse width modulation (PWM). This allows the fan to be configured for maximum performance or virtually silent operation as required - either through automatic, temperature-based control by the mainboard or by means of manual speed controllers such as the NA-FC1.

Stops at 0% PWM

The fan can be brought to a complete standstill by being controlled by the mainboard or a fan controller with a PWM duty cycle of 0%. This makes it ideal for semi-passive systems that switch off the fans at low thermal loads and therefore run completely silently.

Smooth Commutation Drive 2

The latest, advanced version of Noctua's SCD drive system guarantees outstandingly quiet operation by eliminating torque fluctuations and switching noise. This makes the fan amazingly quiet even at close range.

Low-noise adapter

The NF-A14x25 G2 PWM is supplied with a (L.N.A.) that reduces the maximum speed from 1500 to 1250rpm. This allows you to either operate the fan at a constant 1250rpm or limit the maximum speed in PWM mode.

Comprehensive connection options

While the 20cm short primary cable helps to avoid cable clutter in typical applications, the included 30cm extension provides extra reach for all occasions. Both cables are fully sleeved and a 4-pin Y-cable allows a second PWM fan to be controlled at the same connection.

Extended protection functions

Thanks to reverse polarity, overcurrent and overvoltage protection, the fan is also suitable for use in difficult electrical environments. Its extremely low electromagnetic interference emissions also make it ideal for applications where the best possible electromagnetic compatibility (EMC) is required. The protection against locked impeller and overload offers additional safety in situations in which the fan can be mechanically blocked.

Safety certifications Unlike many inexpensive fans, the NF-A14x25 G2 has been thoroughly tested for electronic safety, immunity and interference emissions. Safety certifications from CE, TÜV, UKCA and UL as well as compliance with all applicable standards (EN 62368-1, EN 55035, EN 55032, UL-507) make it a safe, all-round high-quality device.

Elecena nie prowadzi sprzedaży elementów elektronicznych, ani w niej nie pośredniczy.

Produkt pochodzi z oferty sklepu reichelt elektronik